Mastic Asphalt Roofing

Specialist Asphalt Roofing Contractors

Are you in need of some asphalt roofing work. Whether it is a survey, maintenance, repairs or an installation of a new asphalt roof we will be happy to help you. Just get in touch with us via the contact page or call us on 0207 781 8150.

Mastic asphalt roofing, more than 150 years on, is still the most versatile waterproofing system used in the construction industry. This hot molten hand laid seamless material, still continues to provide unbeatable protection from water ingress. Asphalt roofing has evolved over the last 40 years to include advanced polymers giving elasticity to this already durable material. Mastic asphalt roofing can be used to waterproof most types of structural decks such as pre-cast concrete, timber deck and metal decking.

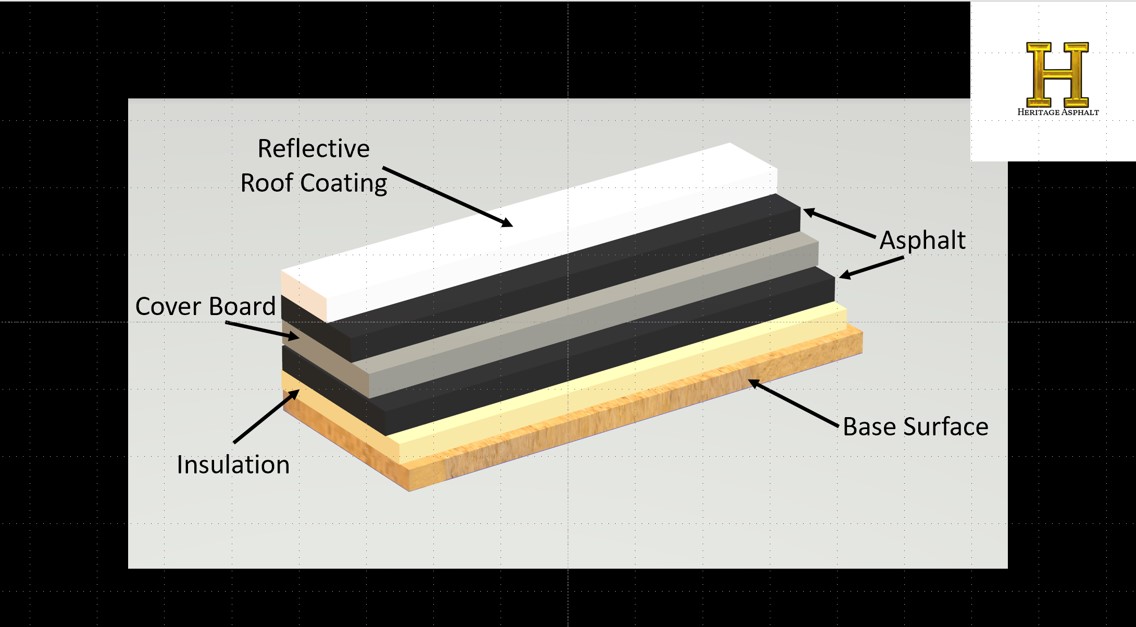

Thermal insulation materials can easily be installed as part of an asphalt roofing specification, also giving the required values. If insulation was required in a roof specification a vapour control layer would need to be installed.

Mastic asphalt roofing can be applied to form a continuous waterproof cover to all types of substrates. It is also ideal for complex detailing as it can easily form around a variety of different details. This includes roof lights and soil vent pipes.

The beauty of asphalt roofing is that it can be hand laid to all rigid substrates from concrete, timber, deck units, metal decking and many other materials. With mastic asphalt it can also be applied to thermal insulation and achieve any required u-value. Asphalt roofing can also be finished with solar protection, extra traction and the capability to endure heavy foot or vehicle traffic on the roof.

Build Up of Asphalt Roofing

The Different Structures an Asphalt Flat Roof can be Laid Upon

Mastic asphalt roofing can be laid on many structures and insulations. Preparation always being the key component to achieving the right finish. Still considered by many as the ‘king’ of waterproofing because of its durability.

Let’s look at all the different structures and the build-up:

Wooden deck roof, 210mm coats to the horizontal to 3no coats on the upstand prepped with sheathing felt and expanded metal lathing. A screeded roof, chase line cut 25mm to 150mm above deck level in height, primed with high bond primer and left to dry 2 coats of mastic asphalt tucked into prepared chase for termination, 2no 10mm coats laid to battens and existing falls levels with sand rubbed finish on sheathing felt which is an isolating membrane for movement, many big structures which have used mastic asphalt for waterproofing lay insulation on top of the asphalt with paving slabs and stones.

This terminology is a cold roof or upside-down roof as air handling units and large ducting is now situated on flat roofs, this preferred option is to allow other tradesman to work around their units without causing damage to the asphalt waterproofing.

A warm roof would consist of lying a vapour control layer over an already primed area, because of the European laws 17 120mm rigid insulation board can be installed with p.u. adhesive setting back around perimeters edges approximately 30mm to allow an asphalt plug to be installed as to stop movement and cracking between structure where channels are installed to a wooden structure.

These channels are installed to run the rainwater away, a hard-wooden edge would be fitted at the height of the insulation to keep a sturdy edge that stops damage when impacted on.

Instead of the asphalt plug used on screeded roofs the E.M.L fitted to wood kerbs would be dressed down on to the onto the insulation allowing movement but no damage to the roof. A lead flashing would be fitted above the kerb dressed down onto asphalt upstands giving the term free standing roof. GRP trims are now fitted to outside edges of roofs this gives an easy on the eye appearance but also more important encapsulation between the asphalt dressed to edge of trim down to the upstands and horizontal areas.

All protrusions i.e. soil vent pipes R.W.O are easily finished to complete the roof. As with all asphalt roofing the use of solar reflect paint upon completion is highly recommended.

An Asphalt Flat Roof Installed by our Team

The Process of Installing an Asphalt Flat Roof

• Before the asphalt is applied to the insulation surface a separating membrane must be laid to the surfaces this can vary from surfaces and specifications, sheathing felt, staple tissue and building paper. It must also allow a free lateral passage for hot air and moisture vapour during the application of hot asphalt and act as a long-term vapour pressure release layer. The membrane is laid with joints of 50mm and is ‘loose laid’ to all horizontal surfaces. Within the grades of asphalt there are special grades in its roof star range and are not limited to black in colour and export grades can be achieved for roofing.

• Permaphalt is a formulation polymer modified and is flexible at low temperatures. All application should be in accordance with B58218 and B5800: Part 4.

• Sloped surfaces up to 10°will be laid on sheathing felt with a total thickness of 20mm in 2no passes, all finishes will need to be solar painted to minimise heat build up through solar radiation.

• On the application to upstand junction (vertical) surface keying must be applied with high bond primer and on bricks/ stonework tucked into a chase line 25mmx 25mm. the upstands will be applied with a trowel on the 1st pass and float applied with the topcoats, formed with no outstanding laps. Surfaces must be clean and dry for bonding to vertical substrates. They key to vertical or sloping timber expanded lathing over black sheathing felt shall be fixed with 25/20mm nails or galvanised staples with 150mm centres. The height of the upstand junctions should be 150mm in height and the total thickness 13mm-20mm, should the asphalt upstand be applied to a freestanding kerb a separating flashing (cover flashing) shall be fitted with the protection of solar paint.

• Special Rwo details with need to be fitted and clamping rings to cast iron or aluminium silicon alloy Rwo with a bellmott opening used as well as (code45) lead shoots fitted and the asphalt formed into and around details.

• Once the field area is complete along with the upstand junction (vertical) a double fillet seal if fitted, this is applied in 2no passes, (warmed cleaned) this seals the horizontal to the vertical. On the roof edges GRP trims can be fitted as well as lead aprons with a bullnose finish to seal roof edges and to pervert a capillary at the above detail.

• Once all items have been applied all surfaces will require a solar a solar reflective coating as a finish in 2no coats, there are a variant of colours which will leave a pleasing finish.

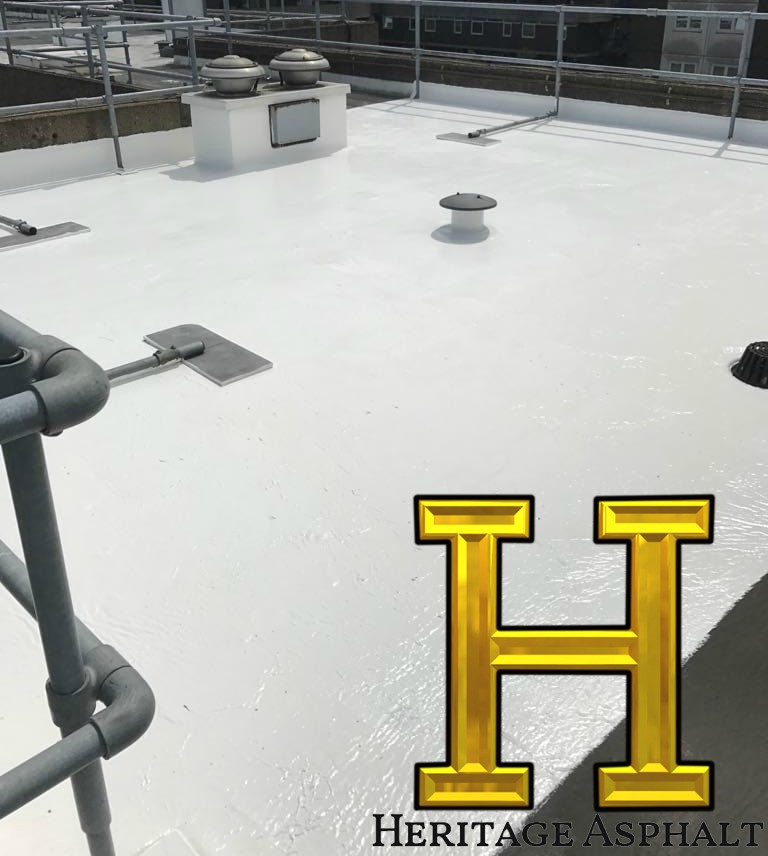

Solar Reflective Paint used on a Completed Asphalt Roofing Project

Asphalt Roofing Advantages

• Of all the waterproofing materials on the market, mastic asphalt roofing has the most advantages. This seamless hot molten liquid can be moulded and dressed to any number of tight awkward areas by highly skilled tradesman. Laid in 20mm thickness, no other waterproof system gives such a solid durable finish compared to other market products, aggregates can also be added to provide many different aspects from flooring to tanking to carparks, this product covers it all.

• Mastic asphalt roofing is carbon zero rated, no other waterproof product comes anywhere near this. With a minimum 2-year N.V.Q required to become a competent asphalt spreader, this far out weights the weeklong courses that are available to start a roofing career in single ply or liquid roofing.

• Totally recyclable - mastic asphalt has now been developed into a unique screed, Permascreed offers a new concrete roof with a screed laid to falls and levels that can be laid on within hours instead of a sand and cement screed that needs 7 days to cure. Another big advantage of this mastic asphalt screed is that it can be left without rainwater ingression into the system, so no core venting is needed to draw the trapped water out that a normal screed would need.

• Large areas can be laid in hot transport loads so the waterproof finish can follow up and push the contract enabling work below to be completed on a much quicker time scale. Solar reflective paint is always specified to mastic asphalt roofing, not only providing a decorative finish but also disperses the heat from the roof, it can also help to resist fungal and vegetation surface growth which often occurs on mineral felt finishes.

An Asphalt Roofing Project in London

Asphalt Roof Inspections

If you think your asphalt roofing is showing signs of failing. It is wise to get a roof inspection before committing to the large cost of full roof replacement. Every year our team inspect roof's which the owner is convinced they are in need of a complete replacement. And in many cases this is not necessary. If it is possible to save your mastic asphalt roof our team will find a way.

Need a Quote or Some Advice Regarding Asphalt Roofing?

If you would like a quotation or any information regarding the repair, maintenance or installation of Asphalt Roofing please get in touch with us via our contact page or call us now on 0207 781 8150. One of our friendly team will be happy to assist you.